MANUFACTURING

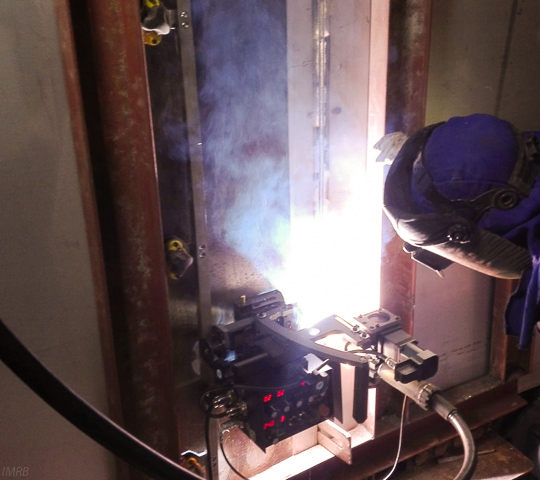

IMRB has a large number of welding procedures and approvals to carry out the work with the greatest satisfaction for our customers.

We have experience in the use of all types of metallic materials: carbon steels, alloy steels, stainless steels, bimetals, etc.

All the materials we work with are of high quality and are certified according to regulations and at the request of the client.

Usual productions:

- Pressure elements of boilers

- Boiler wall panels with longitudinal membrane or fin

- Components of the pressure body of water-tube and tube-tube boilers

- Pressure equipment and tanks

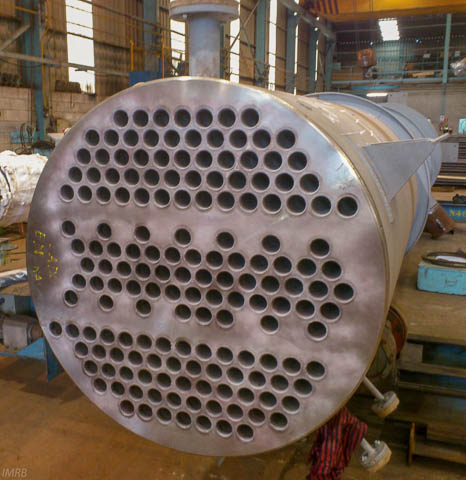

- Heat exchangers

- Reloaded pipes with straight and curved anti-erosion and anticorrosion welding

- Industrial pipes

- Various conveyors for different substances (endless screws, belts, redler, bucket elevators, feeding and unloading tables ...)

- Refinery air coolers

- Welding reloads in parts with a high demand for wear and temperature, such as coal burner boxes for boilers in thermal power plants or biomass boiler output superheater tubes. In both cases, with satisfactory experience

Development of more than 300 welding procedures.

Technical manufacturing standards. ASME code

Materials:

Carbon steels. Low alloy steels. Stainless and refractory steels. Stainless duplex steels with austenitic metallographic structure on a ferritic matrix. Materials with cladding or composite anticorrosive coating.

- Pressure elements of boilers

- Boiler wall panels with longitudinal membrane or fin

- Components of the pressure body of water-tube and tube-tube boilers

- Pressure equipment and tanks

- Heat exchangers

- Reloaded pipes with straight and curved anti-erosion and anticorrosion welding

- Industrial pipes

- Various conveyors for different substances (endless screws, belts, redler, bucket elevators, feeding and unloading tables ...)

- Refinery air coolers

- Welding reloads in parts with a high demand for wear and temperature, such as coal burner boxes for boilers in thermal power plants or biomass boiler output superheater tubes. In both cases, with satisfactory experience

Development of more than 300 welding procedures.

Technical manufacturing standards. ASME code

Materials:

Carbon steels. Low alloy steels. Stainless and refractory steels. Stainless duplex steels with austenitic metallographic structure on a ferritic matrix. Materials with cladding or composite anticorrosive coating.

For the realization of the activity we have, among others:

- • Approved equipment for verification / calibration of instruments

- • Equipment for the realization of thermal treatments to welds

- • Equipment required for hydraulic tests

- • Machinery for bending and forming of pipes

- • Machinery for cutting (oxy-plasma) and sheet metal folding

- • Machinery for turning and machining parts

- • Equipment for blasting and priming parts

- • Special welding machines

- • Table for welding pipe fins

- • Welding positioners

- • Welding Column for Submerged Arc Procedure SAW

- • Turners used in welding column or in cylindrical equipment processes

- • Own tool repair and maintenance workshops